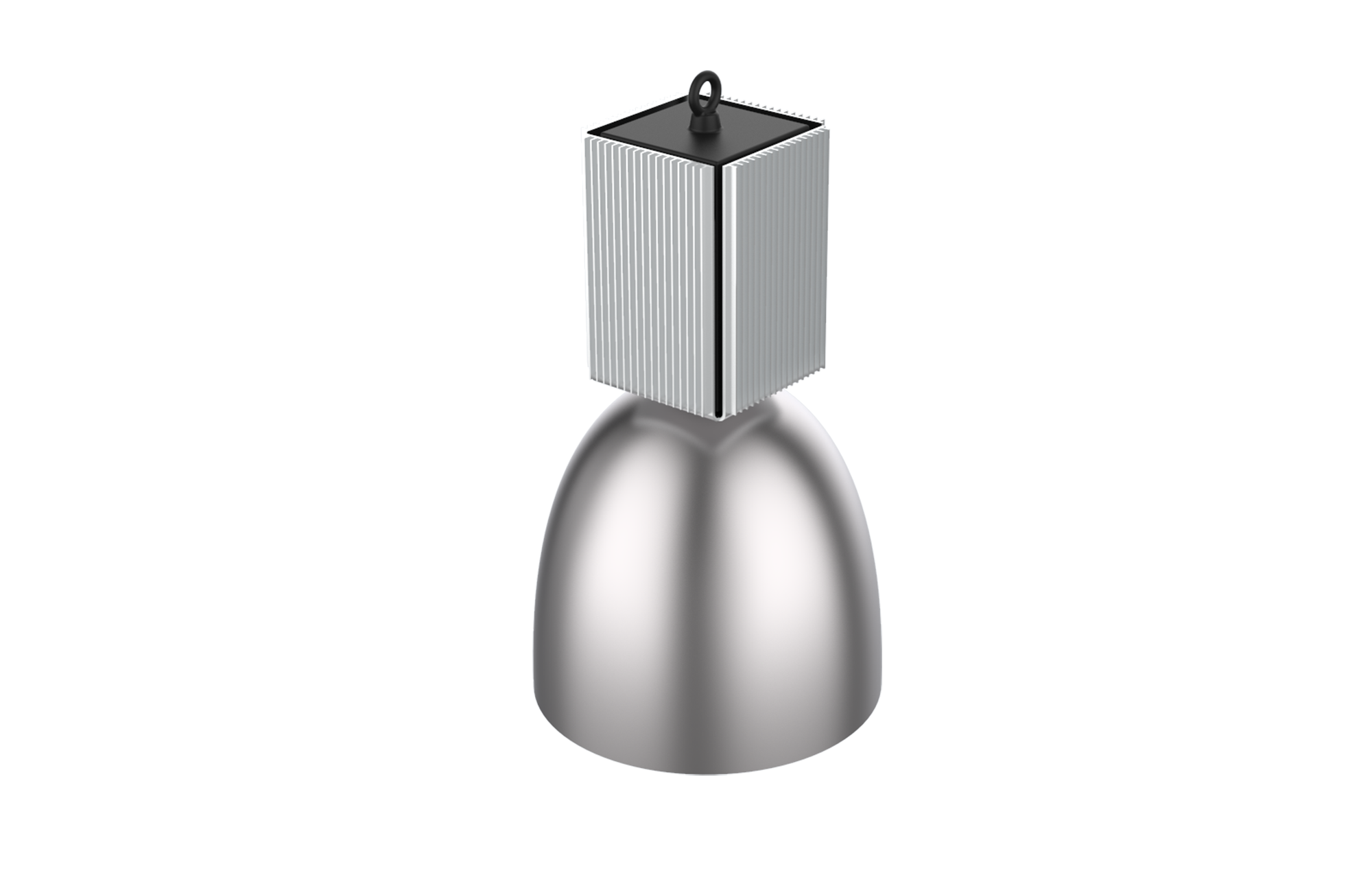

Segri-COOL SOLUTION

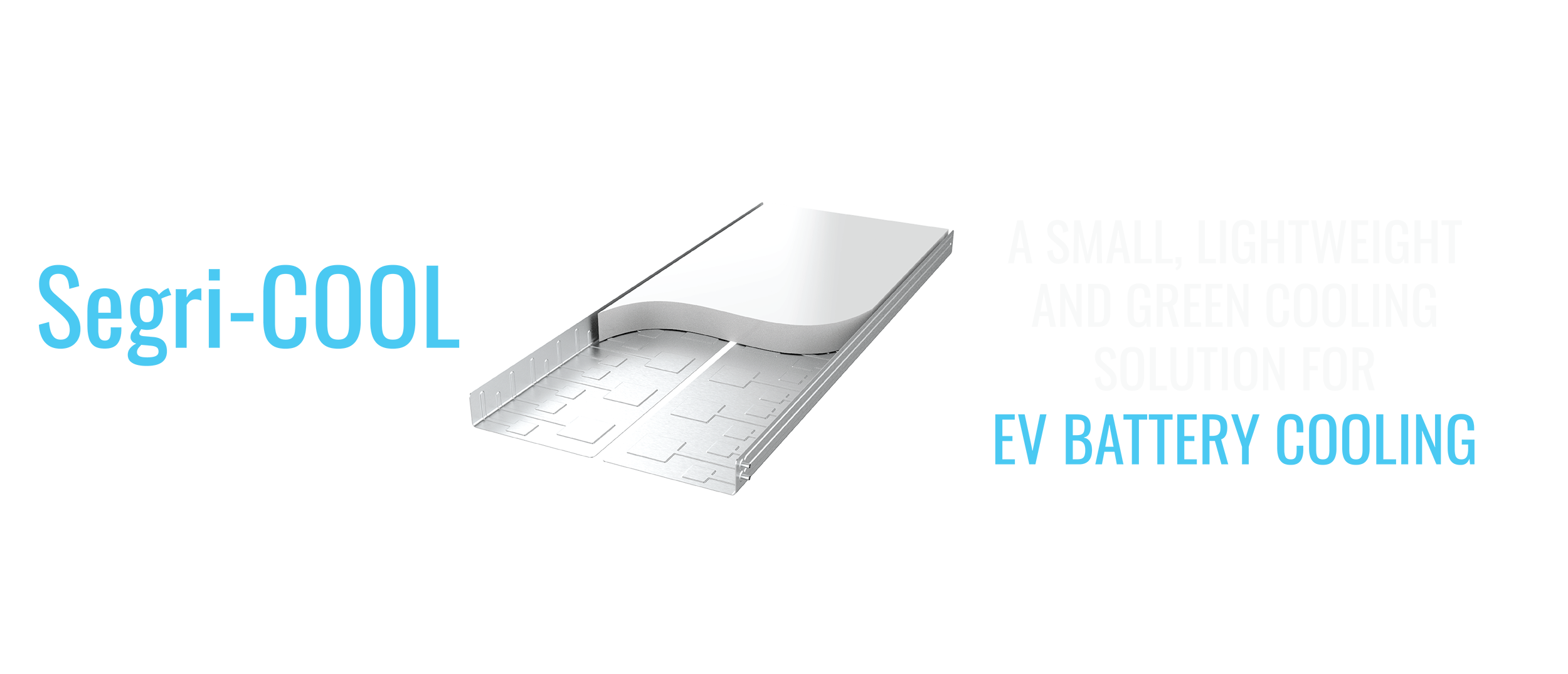

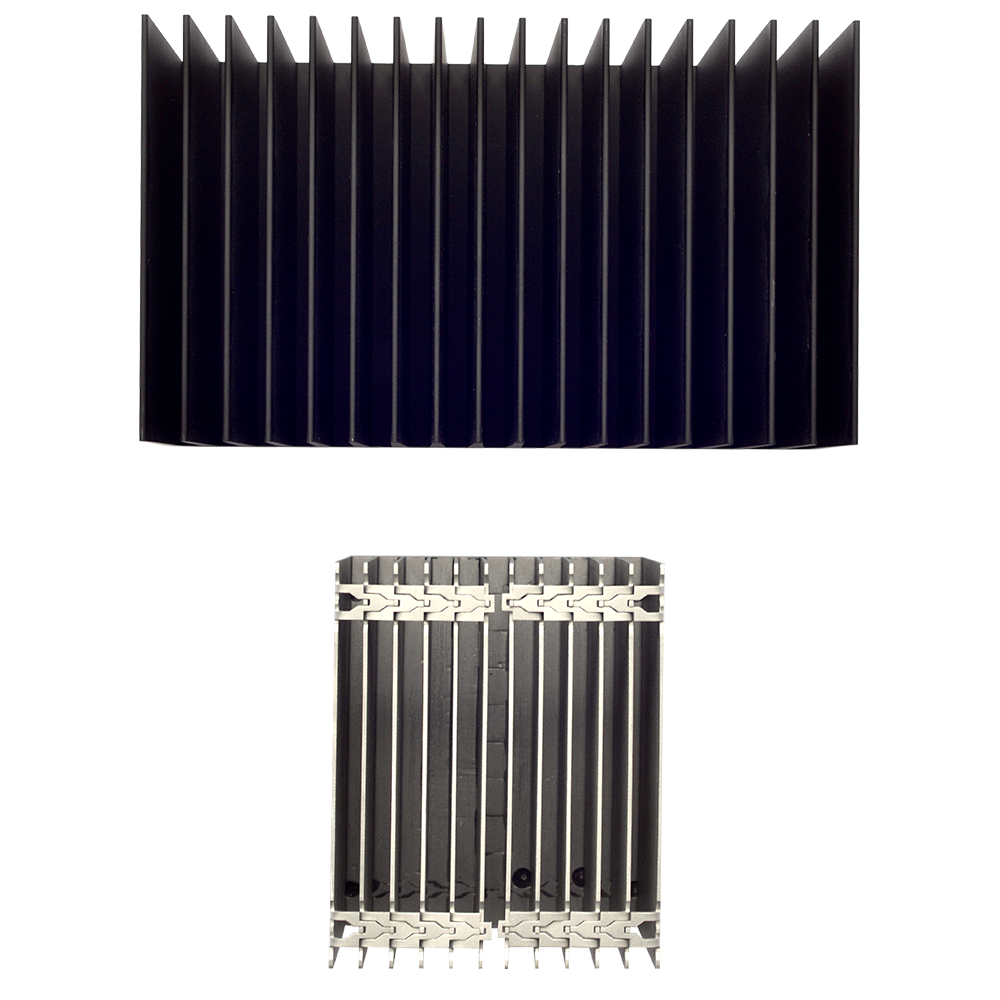

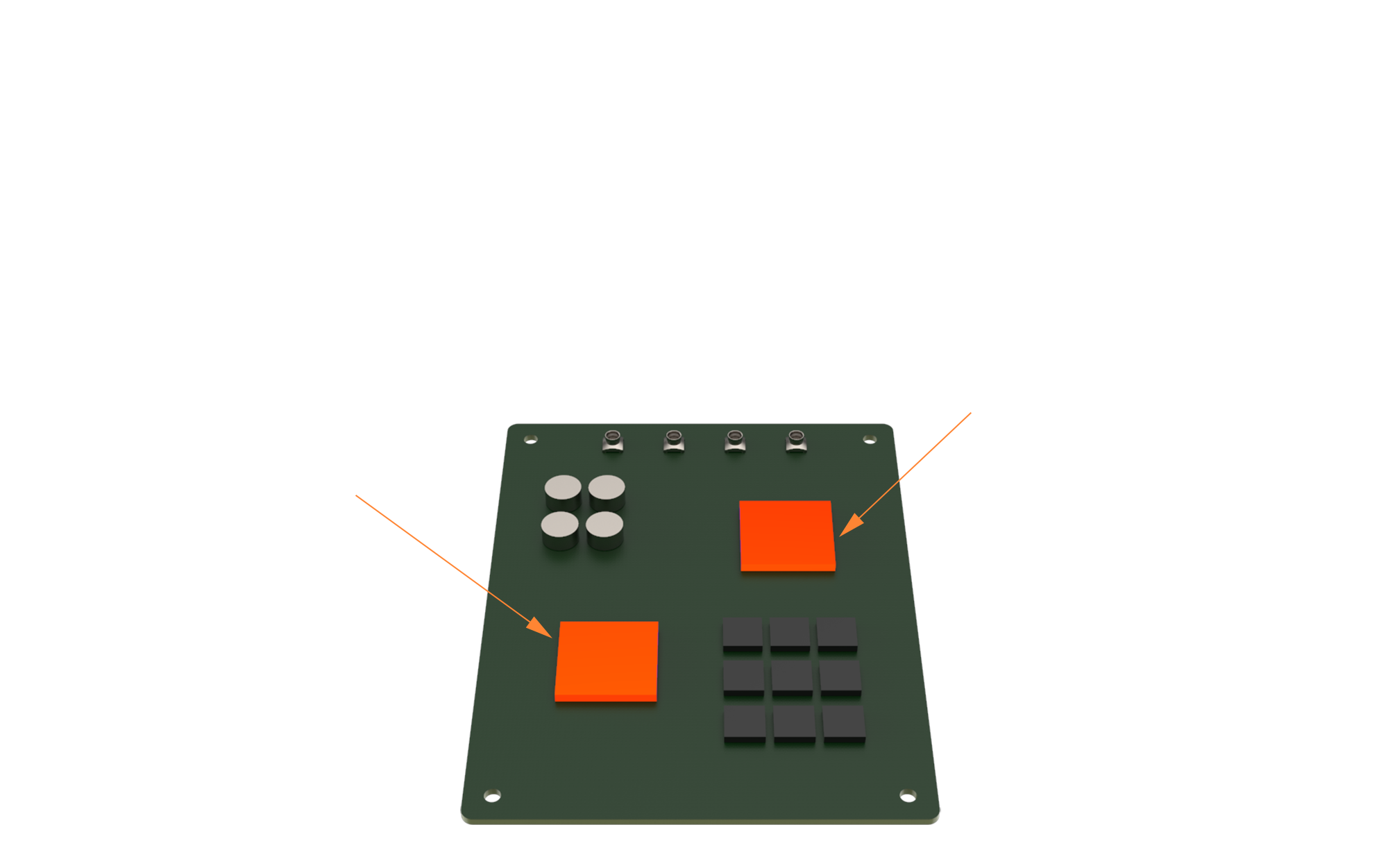

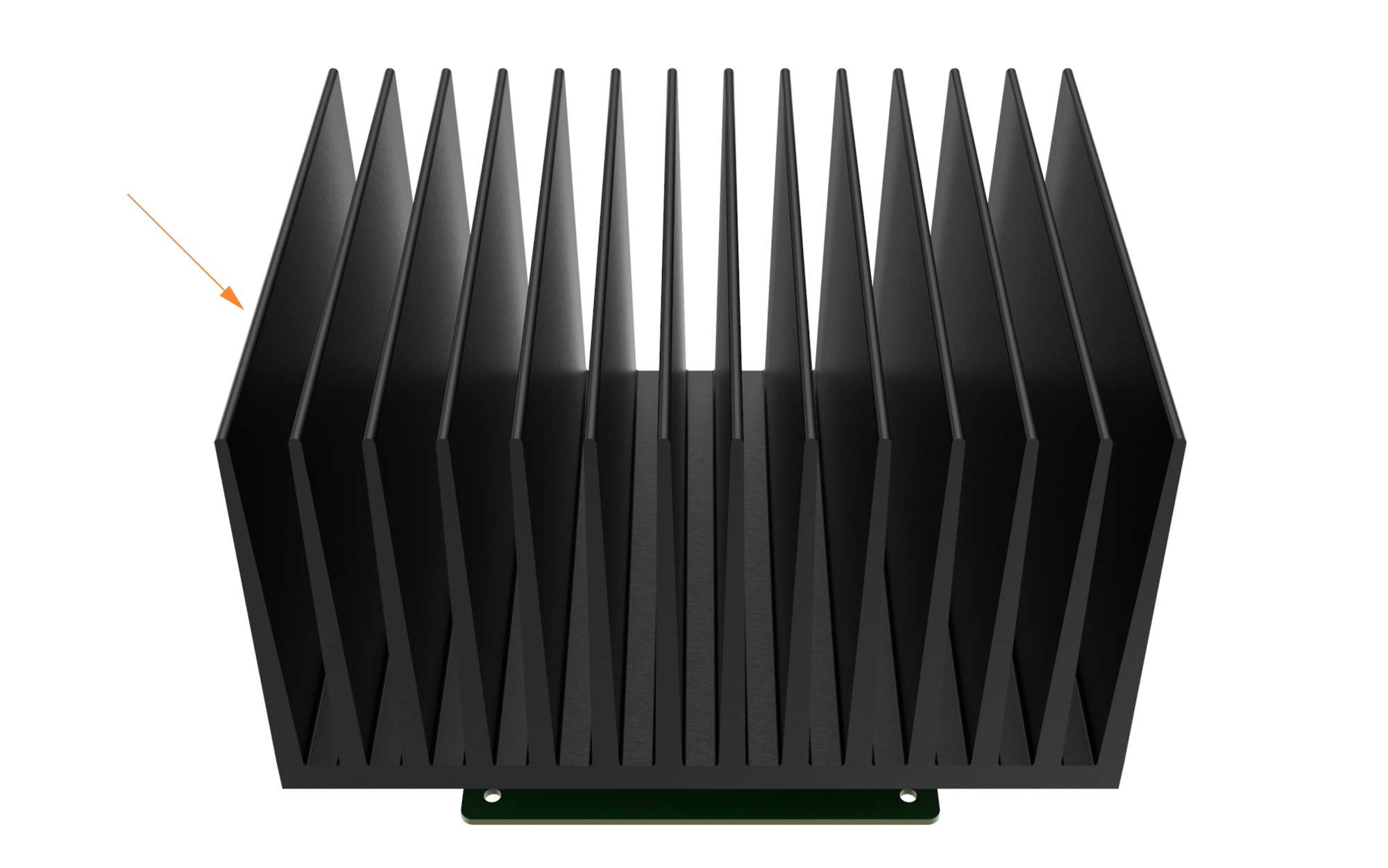

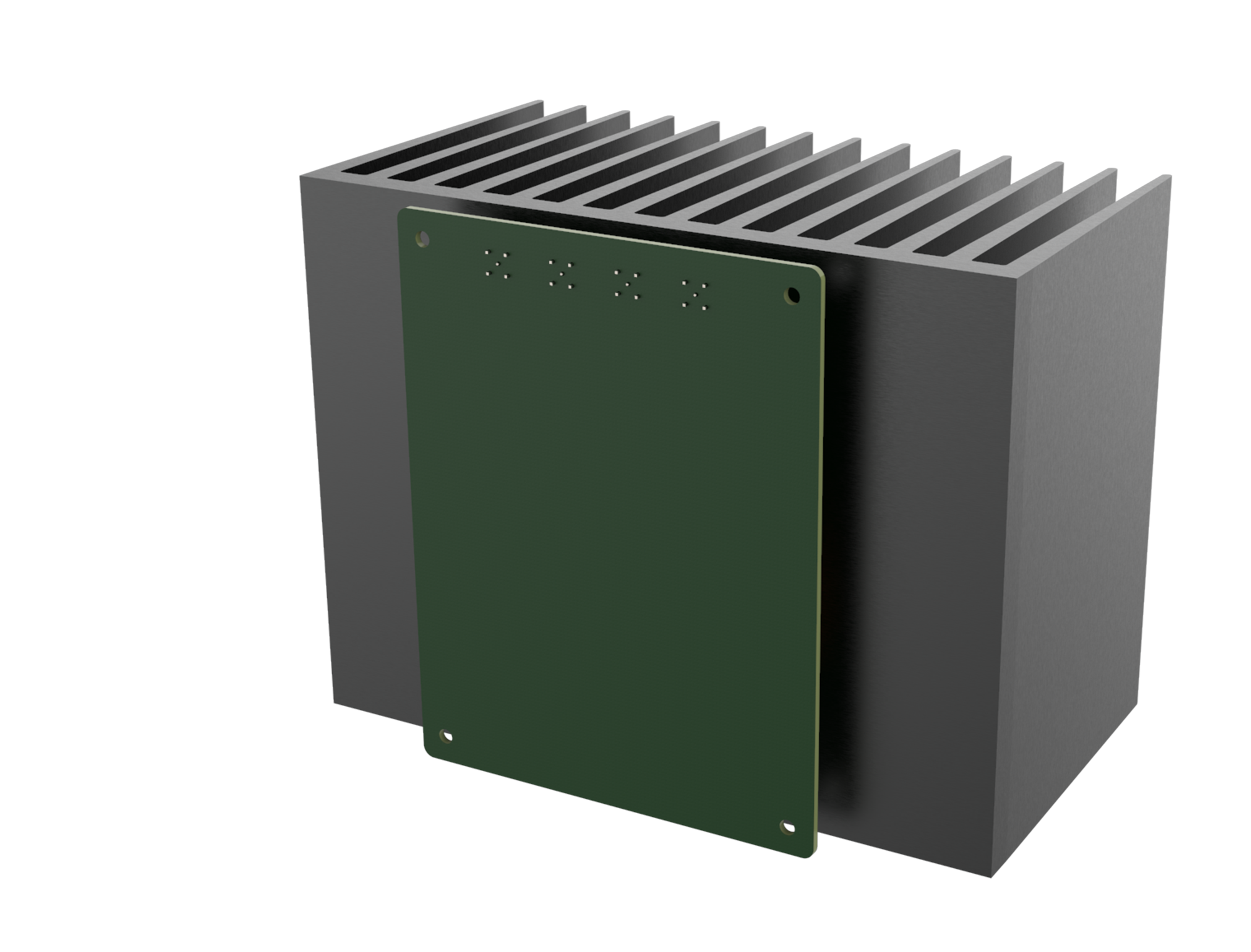

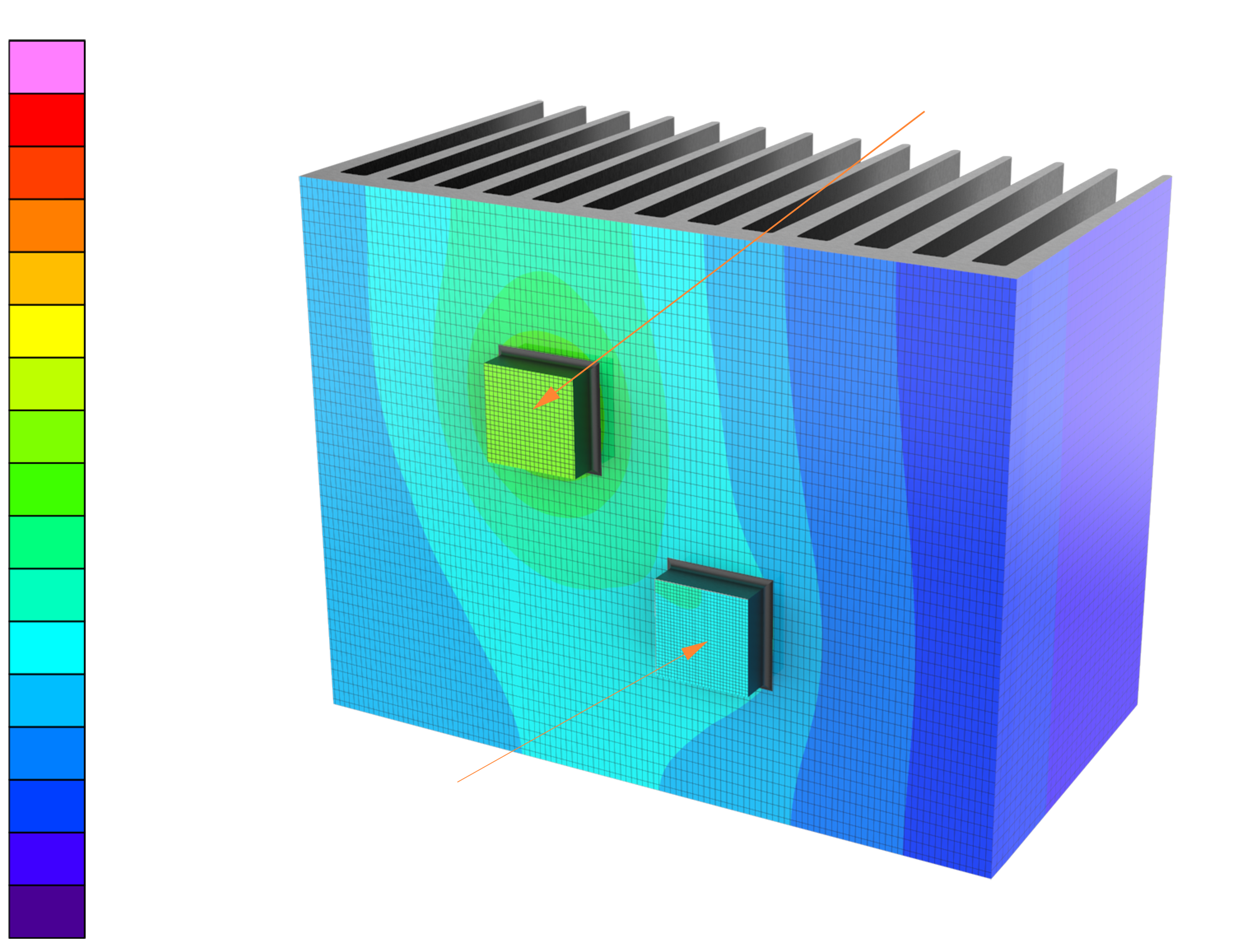

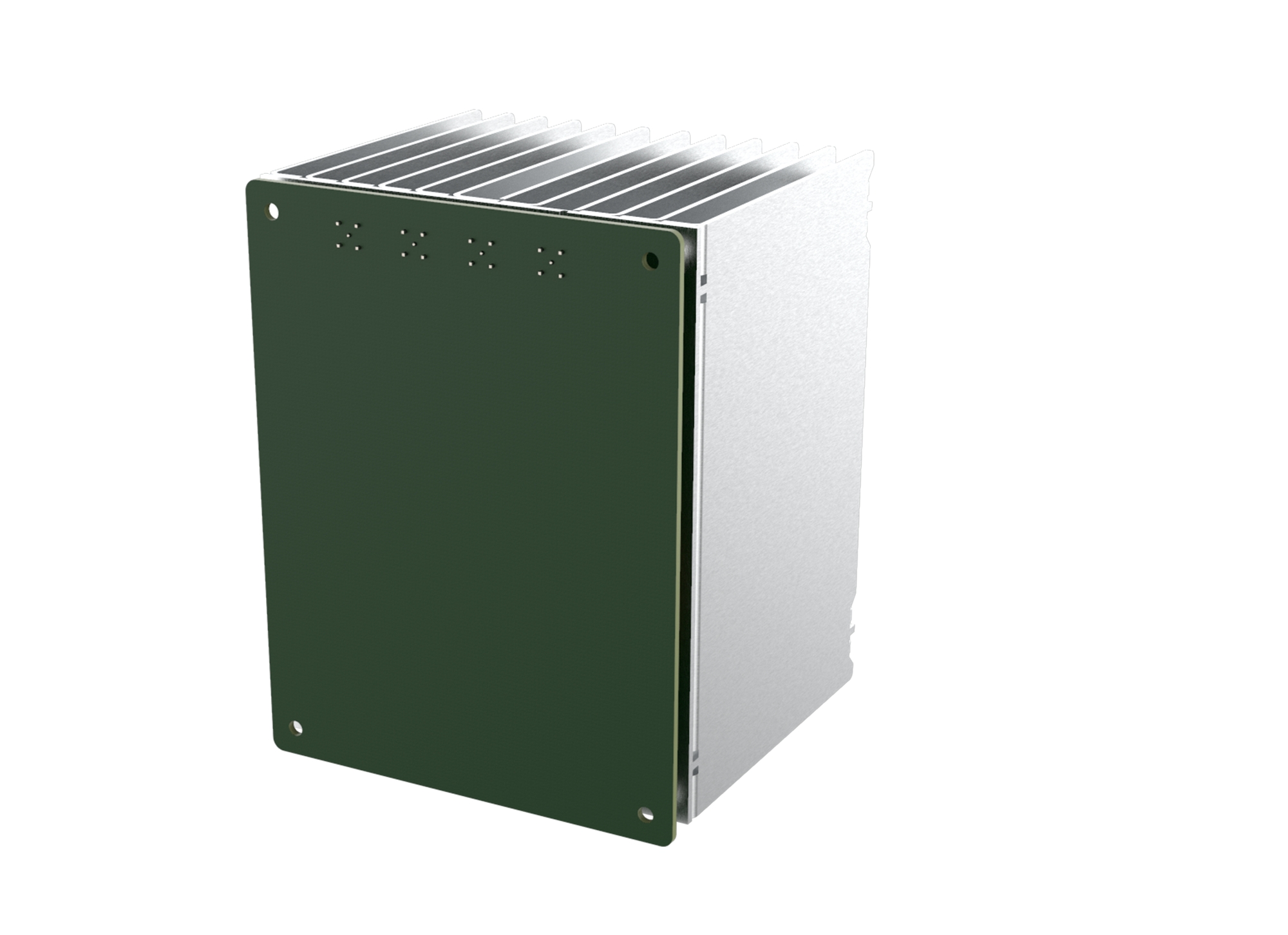

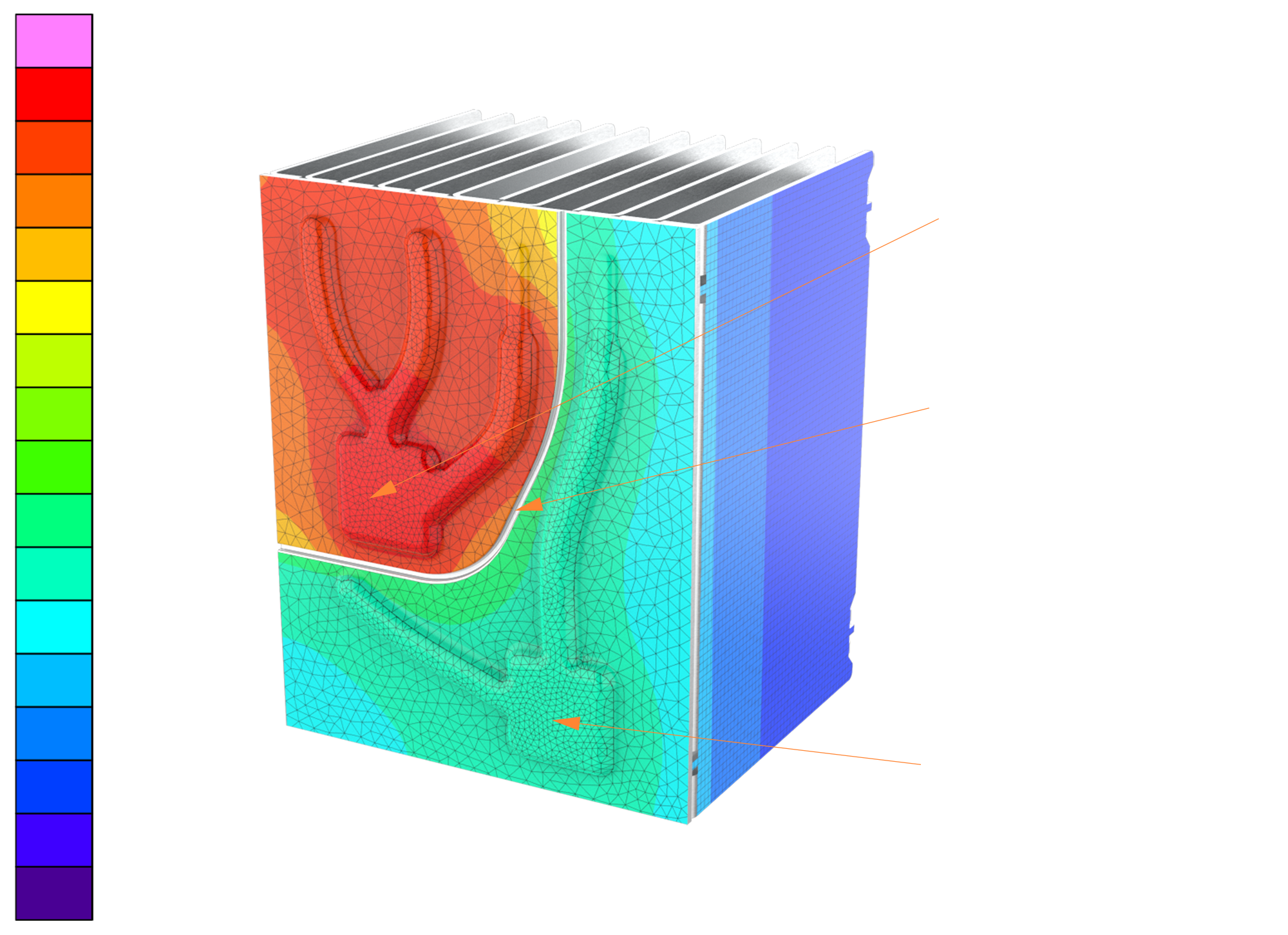

With our patented Segri-COOL heat sink, we can efficiently cool all board components within their respective operating limits. The result is a significantly smaller and lighter heat sink, and therefore smaller and lighter product. The Segri-COOL heat sink shown weighs just 0.77 kg and occupies a volume of 1.5 liters, making it 70% lighter and 45% smaller than the die cast solution.

REDUCE TOTAL COST OF OWNERSHIP WITH Segri-COOL

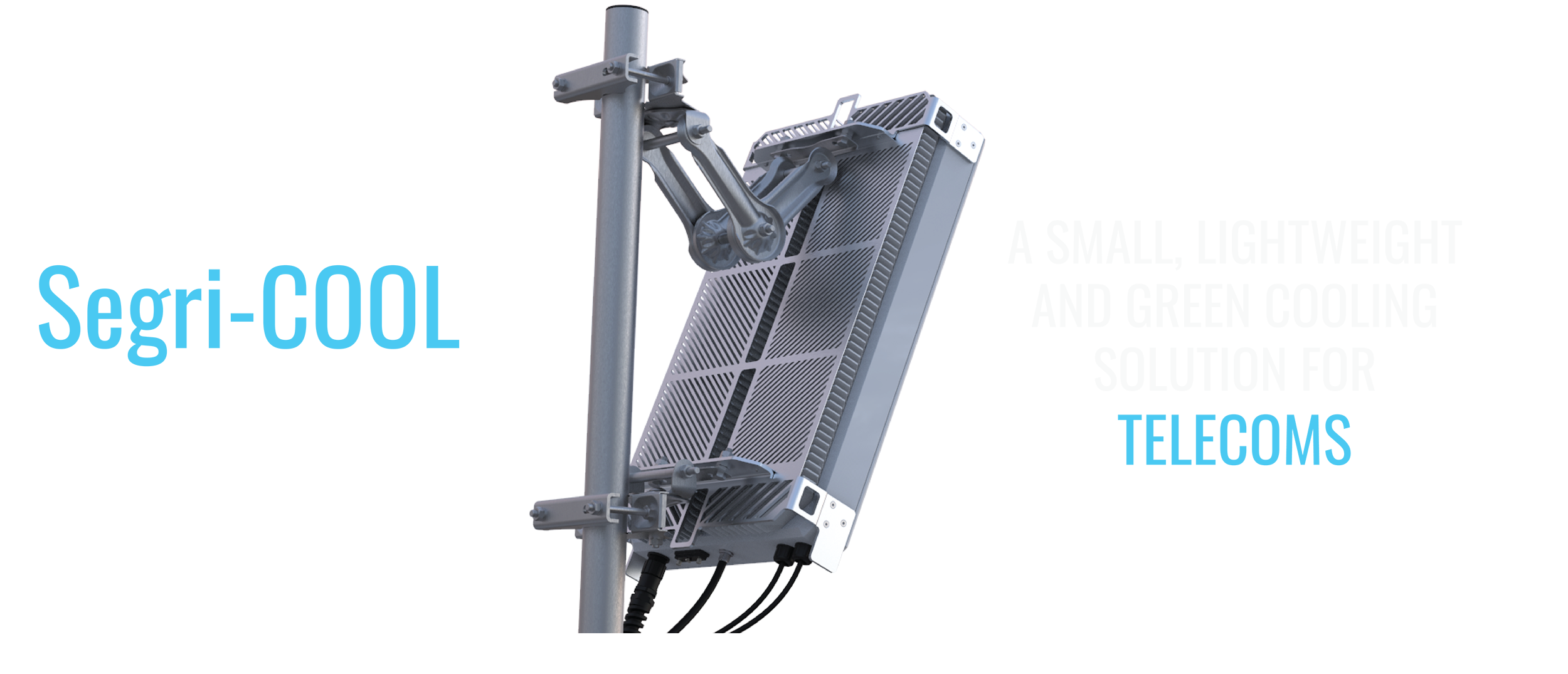

The telecommunications industry grapples with a considerable challenge: keeping products cool within a compact and lightweight design. While Radio Access Network (RAN) hardware equipment costs represent approximately 5% of the Total Cost of Ownership for Communication Service Providers (CSPs), site construction, installation, and rental constitute approximately 35%, with each aspect significantly influenced by hardware size and weight.

Segri-COOL, being smaller and lighter, has the potential to reduce installation, transport, construction, and OpEx costs for the operator.